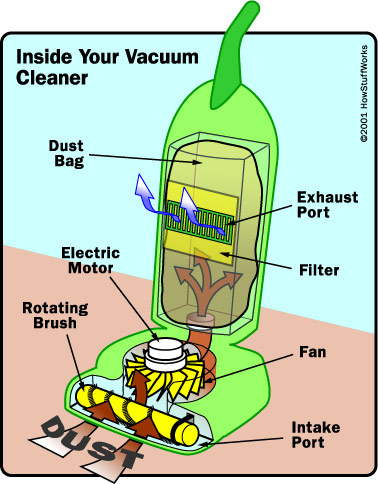

- The Fan

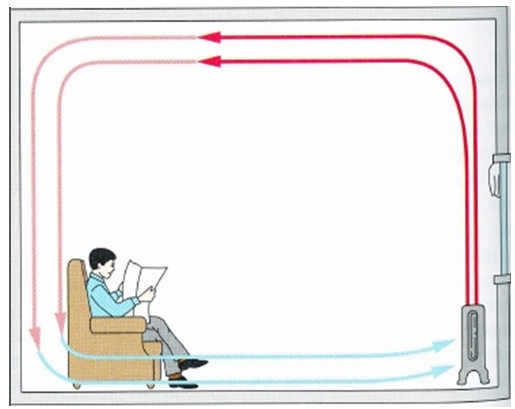

The vacuum cleaner has a good-speed fan to create the swiftly moving air which

sweeps up the dust. More precisely, when you switch on the vacuum cleaner, the fan inside rotates

and hence pumps air from the hose (that is the inlet, a low pressure region) to the exhaust port

(the high pressure region). A partial vacuum

is created (hence the name 'vacuum cleaner') in the hose and the surrounding air rushes into the vacuum cleaner

through the hose. Recall that the pressure drop inside the vacuum cleaner can be

explained using the Bernoulli's principle, readers are suggested to review the principle again in

the section 'Shower Curtain' in chapter 2.

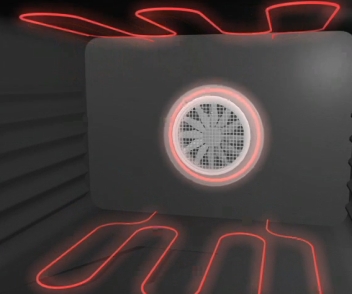

The vacuum cleaner has a good-speed fan to create the swiftly moving air which

sweeps up the dust. More precisely, when you switch on the vacuum cleaner, the fan inside rotates

and hence pumps air from the hose (that is the inlet, a low pressure region) to the exhaust port

(the high pressure region). A partial vacuum

is created (hence the name 'vacuum cleaner') in the hose and the surrounding air rushes into the vacuum cleaner

through the hose. Recall that the pressure drop inside the vacuum cleaner can be

explained using the Bernoulli's principle, readers are suggested to review the principle again in

the section 'Shower Curtain' in chapter 2.

- The attachments

The size of the opening at the end of the intake port governs the speed of the air flow. The narrower attachments can increases the air speed and thus decreases the pressure there, because of Bernoulli's principle. The drop in pressure translates to a greater suction force, that's why the narrower attachment can pick up heavier dirt particles than wider attachments.

- The Viscous Drag

High-speed air rushes toward the opening of the cleaning attachment, it carries dust with it. This phenomenon, in which a particle or portion of fluid is carried along in the flow of another fluid, is called entrainment. Dust particles are entrained in air by drag forces. These are friction-like forces, the viscous drag force, which bring the dust particles to move along with the air.Unfortunately, viscous drag also slows the air as it passes close to carpet fibers or the surface of the floor. It's hard to keep air moving quickly near those surfaces. Removing really ground-in dirt from a carpet or floor requires a powerful fan and the high air speed that comes from making air pass through a narrow opening. The need for high air speed also explains why battery-powered or poor-quality vacuum cleaners don't clean well.

In fact, the dust particles are at rest relative to the moving air. Practically, the magnitude of the viscous drag force acting on the dust particle is proportional to the particle diameter and to the difference in velocities between the particle and the air. The viscous drag is directed to bring the particle to the same velocity as the air.

- The Filter

A filter blocks the dust particles while permitting air molecules to pass. A typical

filter is made of porous paper or cloth, with fibers that are loosely woven to create openings or

pores large enough for air to pass, but too small for dust to pass. Generally, there are

supplementary filters to separate the fan from the suction capacity (see the figure next to

the section about 'The Fans'. However, the

filtration is complicated by the viscous drag. The air passes through the filter's pores loses some of its total

energy trying to move past the stationary air at the surfaces of the pores. Since

the viscous drag force on

the air becomes larger when the air's speed through a pore increases. The faster air moves through a pore, the

more energy it loses during the trip. To minimize the energy lost to viscous drag, the vacuum

cleaner must move the air slowly

through the filter. It does this by using a very large filter so that the air has lots of surface area and many pores

through which to flow.

A filter blocks the dust particles while permitting air molecules to pass. A typical

filter is made of porous paper or cloth, with fibers that are loosely woven to create openings or

pores large enough for air to pass, but too small for dust to pass. Generally, there are

supplementary filters to separate the fan from the suction capacity (see the figure next to

the section about 'The Fans'. However, the

filtration is complicated by the viscous drag. The air passes through the filter's pores loses some of its total

energy trying to move past the stationary air at the surfaces of the pores. Since

the viscous drag force on

the air becomes larger when the air's speed through a pore increases. The faster air moves through a pore, the

more energy it loses during the trip. To minimize the energy lost to viscous drag, the vacuum

cleaner must move the air slowly

through the filter. It does this by using a very large filter so that the air has lots of surface area and many pores

through which to flow.

- Blockage

Blockage is a regular problem in most vacuums. When debris builds up in the vacuum bag, the air faces greater resistance on its way out. Each particle of air moves more slowly because of the increased drag. This is why a vacuum cleaner works better when you've just replaced the bag than when you've been vacuuming for a while.

- Bagless Vacuum Cleaner

It is the cyclone vacuum cleaner that uses no bag as its filter. This machine, developed in the 1980s by James Dyson, sends the air stream through one or more cylinders along a high speed spiral path. The spiraling motion works something like a clothes dryer: As the air stream whips around in a circle, all of the dirt particles experience a powerful centrifugal force; they are thrown outward, away from the air stream. In this way, the dirt is extracted from the air without using any sort of filter. It simply collects at the bottom of the cylinder.In the future, we are sure to see more improvements on the basic vacuum-cleaner design, with new suction mechanisms and collection systems. But the basic idea, using a moving air stream to pick up dirt and debris, is most likely here to stay for some time.

- When the air's velocity is less than about 300 km/hr, and if there are no pressure differences of more than one tenth of an atmosphere - then we can consider air to be incompressible, since its density will remain fairly constant.

- The gravity is also ignored, since the air was flowing up and down within a small altitude.

- Always bear in mind that Bernoulli's effect is applied when fluid is in steady flow. In other words, the effect occurs only along a streamline.

In 1907, the first electric portable vacuum cleaner was invented by Murray Spangler in Ohio, since then it has

become an indispensable home appliance for most people. The right picture (Credit: The Hoover Company)

shows a vacuum cleaner in the old days.

Conventional vacuum cleaners use a fan to

create a partial vacuum and suck dirty air from carpets, rugs, and bare floors through a porous bag.

Tell it simply, the vacuum cleaner works like your sipping of juice through a drinking straw.

Air passes through the porous bag but dust is left behind in the

bag, which can be disposed to the outside of the vacuum cleaner.

As the bag in a conventional vacuum cleaner fills

with dust, its pores become clogged so air can no longer flow through so easily.

This clogging reduces the power of suction. The dual cyclone cleaner has no bag to clog,

and retains its cleaning effectiveness.

In 1907, the first electric portable vacuum cleaner was invented by Murray Spangler in Ohio, since then it has

become an indispensable home appliance for most people. The right picture (Credit: The Hoover Company)

shows a vacuum cleaner in the old days.

Conventional vacuum cleaners use a fan to

create a partial vacuum and suck dirty air from carpets, rugs, and bare floors through a porous bag.

Tell it simply, the vacuum cleaner works like your sipping of juice through a drinking straw.

Air passes through the porous bag but dust is left behind in the

bag, which can be disposed to the outside of the vacuum cleaner.

As the bag in a conventional vacuum cleaner fills

with dust, its pores become clogged so air can no longer flow through so easily.

This clogging reduces the power of suction. The dual cyclone cleaner has no bag to clog,

and retains its cleaning effectiveness.

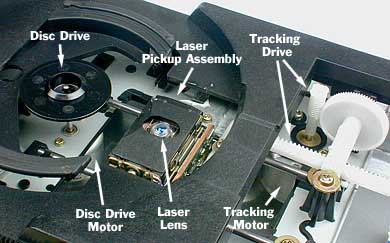

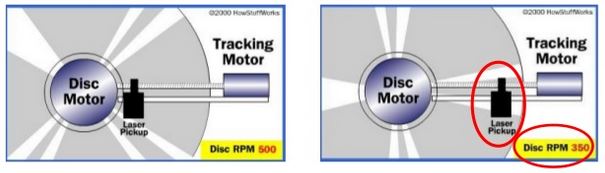

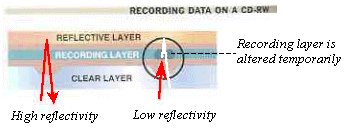

The fascinating work of CD technology is to read all the tiny bumps correctly, in the right order, at the

right speed. In fact it is not a trivial job since the movement of the laser is at micron resolutions.

To achieve this, the CD player has to be exceptionally precise when it focuses the infrared laser on the

track of bumps. When you play a CD, the laser beam passes through the CD's polycarbonate layer, reflects off

the aluminum layer, and hits an optoelectronic device that detects changes in light. The bumps reflect

light differently than the

flat parts of the aluminum layer, which are called lands. The optoelectronic sensor detects this change in

reflectivity, and the electronics in the CD player's driver interpret the changes as data bits.

The most difficult job of the CD player is to keep the laser beam centered on the data track.

This centering is the job of the tracking system.

The fascinating work of CD technology is to read all the tiny bumps correctly, in the right order, at the

right speed. In fact it is not a trivial job since the movement of the laser is at micron resolutions.

To achieve this, the CD player has to be exceptionally precise when it focuses the infrared laser on the

track of bumps. When you play a CD, the laser beam passes through the CD's polycarbonate layer, reflects off

the aluminum layer, and hits an optoelectronic device that detects changes in light. The bumps reflect

light differently than the

flat parts of the aluminum layer, which are called lands. The optoelectronic sensor detects this change in

reflectivity, and the electronics in the CD player's driver interpret the changes as data bits.

The most difficult job of the CD player is to keep the laser beam centered on the data track.

This centering is the job of the tracking system.

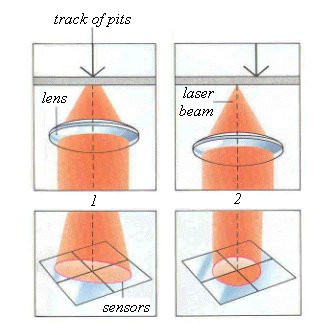

An elegant system which ensures a correct tracking works in the following ways.

If focus and tracking are correct, the reflected light forms

a circular spot spread equally over the four sensors. If focus or tracking are 'out' the spot formed is

either skewed (case [1]) or uneven in intensity (case [2]). The right figure illustrates the two cases.

These irregularities in the distribution of light over the four

sensors are translated

into movements of two tiny motors that move and refocus the beam.

An elegant system which ensures a correct tracking works in the following ways.

If focus and tracking are correct, the reflected light forms

a circular spot spread equally over the four sensors. If focus or tracking are 'out' the spot formed is

either skewed (case [1]) or uneven in intensity (case [2]). The right figure illustrates the two cases.

These irregularities in the distribution of light over the four

sensors are translated

into movements of two tiny motors that move and refocus the beam.

The manufacturers produce CDs by creating a mold of the bump pattern. The mold then presses the blank CD's acrylic surface

and maintain the production a cost-effective approach. But it is not practical for the casual consumer. Home CD burners

come at the problem from a different angle. Nowadays, CD burners are standard equipment on new computers, and the cost of

a blank CDs is lower than a floppy disc.

The manufacturers produce CDs by creating a mold of the bump pattern. The mold then presses the blank CD's acrylic surface

and maintain the production a cost-effective approach. But it is not practical for the casual consumer. Home CD burners

come at the problem from a different angle. Nowadays, CD burners are standard equipment on new computers, and the cost of

a blank CDs is lower than a floppy disc.

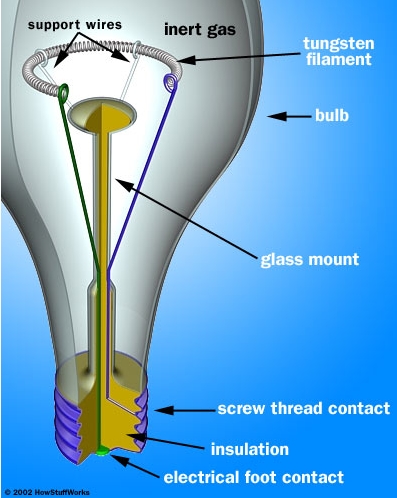

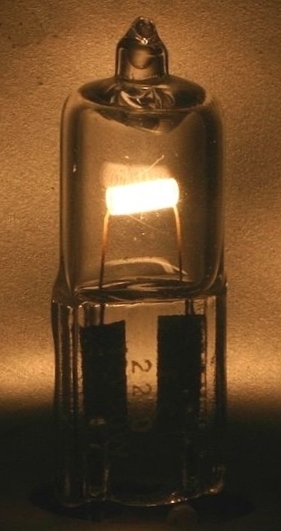

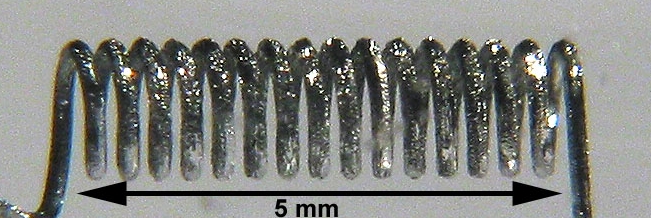

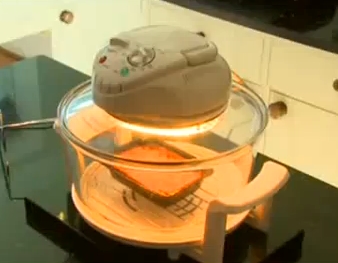

Halogen lamp contains a small amount of halogen gas inside the envelope and it produces light with higher luminous than ordinary light bulb.

The halogen gas also helps to increase both the operation temperature and the life of a tungsten filament.

Halogen lamp contains a small amount of halogen gas inside the envelope and it produces light with higher luminous than ordinary light bulb.

The halogen gas also helps to increase both the operation temperature and the life of a tungsten filament.

Title page

Title page